Wet paint coating

Colourful wet paint coatings fulfil decorative purposes in addition to corrosion protection. High-quality, permanently adhesive plastics are used for the coating.

Wet paint coating: plastics as corrosion protection

During the wet paint coating process, liquid coating substances are generally applied to the surface of the steel made product, or galvanised steel as a corrosion protection. Afterwards, these harden. The coating substances consist of plastic, and later form a highly adhesive covering. Depending on the requirements, loads and required corrosion protection, several paint layers are applied by our partner companies.

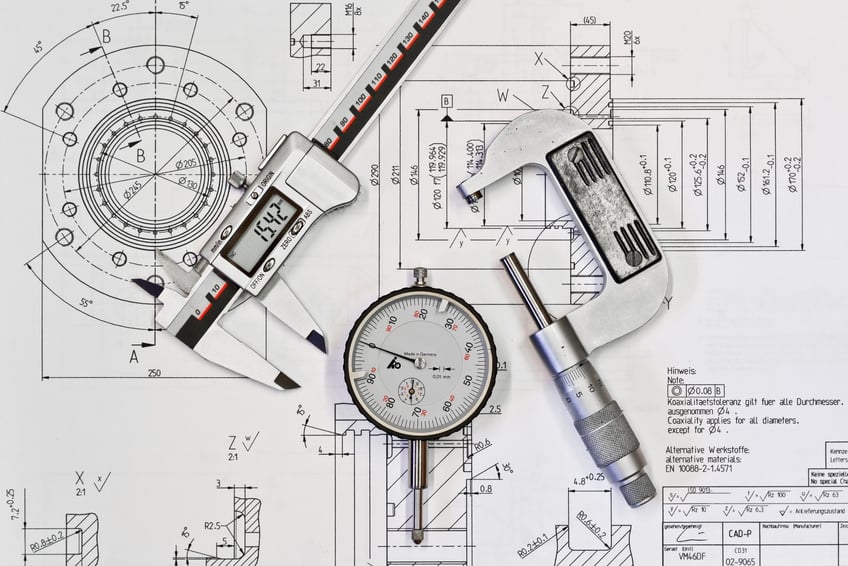

Wet paint coating – your advantages at a glance:

RAL, NCS and Pantone colours possible.

Wet paint coatings can also be executed after assembly of the components on the construction site.

You can achieve a high surface quality through the wet paint coating.