Hot-dip galvanising in Europe's most modern galvanising plant group

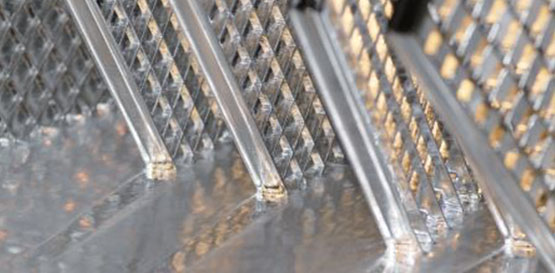

HOT-DIP GALVANISING IS THE PERFECT CORROSION PROTECTION FOR STEEL. THE LONG-LASTING, MAINTENANCE-FREE AND ENVIRONMENTALLY-FRIENDLY PROPERTIES OF THIS CORROSION PROTECTION REMAIN UNEQUALLED. AND WHERE BETTER TO CONDUCT THE GALVANISING PROCESS THAN IN THE GALVANISING PLANTS OF THE MOST MODERN GALVANISING GROUP IN EUROPE?

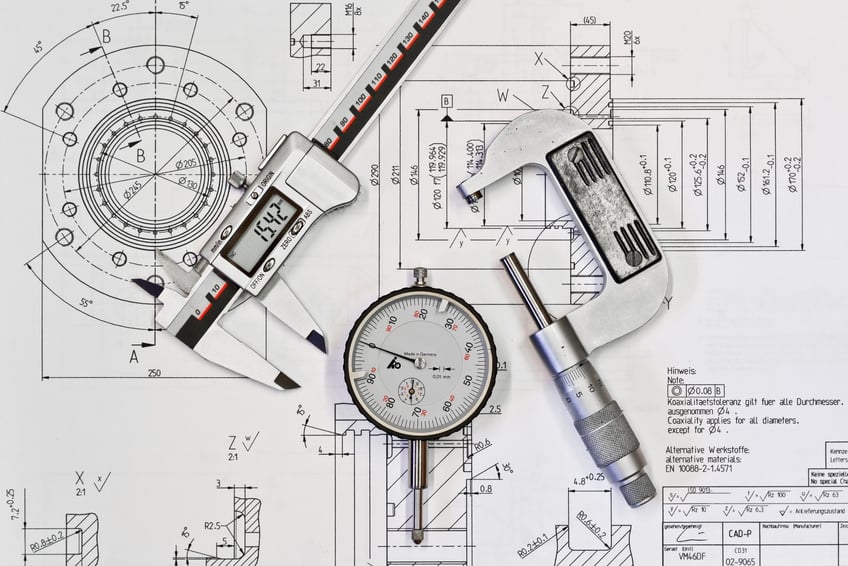

What began in 2001 with our galvanising plant in Stadtlohn was continued in 2009 with a new galvanising plant construction in Sulz am Neckar, and optimally supplemented at the end of 2013 with our latest galvanising plant in Heek. Using computer supported processes and the most modern plant technology currently available, we and our experienced employees guarantee maximum, reproducible quality, as well as short lead times. In this way, know-how coupled with the latest galvanisation technology flows into our production and leads to high-quality results.

We act on our service principles!

Our services for you:

- Application and construction consulting

- Advice on questions regarding further material processing (e.g. coatings)

- Large, own vehicle fleet; regular tour service

- Above-average adherence to delivery deadlines

- Extremely short throughput times

- High-quality surfaces

- Constant quality through ultra-modern galvanising technology

- Everything from a single source - further surface treatments such as duplex coatings are available from partner companies in the region

- Processing, further processing and order-picking possible