Hot-dip galvanising

Hot-dip galvanising is an extremely durable form of corrosion protection, and therefore ideal for steel. The long lasting, maintenance free and environmentally friendly properties of this corrosion protection method remain unequalled.

Hot-dip galvanising: The perfect corrosion protection

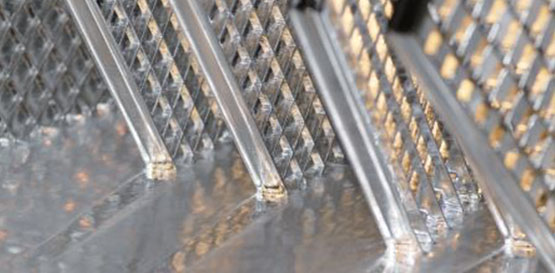

During the hot-dip galvanising process, steel parts are submerged into molten zinc so that a zinc layer forms on the surface of the steel. In this way, we achieve a particularly effective protection for your products against corrosion which generally lasts up to 100 years (DIN EN ISO 14713-1). The protection duration after hot-dip galvanising is strongly dependent on atmospheric, mechanical, chemical and thermal influences.

Hot-dip galvanising – your advantages at a glance:

The hardness of the iron-zinc alloy layer lies substantially over the hardness of normal construction steels, and it is therefore much more resistant to mechanical loads such as impacts, shocks and abrasion which can occur during transport, assembly or during use.

The zinc layer thicknesses in edge areas are generally particularly strong due to the chemical bond between steel and zinc, which leads to optimum protection, also in areas at risk of corrosion and cavities.

Extreme weather conditions may cause the zinc layer to abrade slightly. However, the duration of protection can be determined based on the zinc layer thickness and the object location, so that the galvanisation remains a reliable protection against corrosion.

However, should small amounts of damage occur to the zinc surface due to the chemical reactions between steel, zinc and humidity, the steel in the area of the damage will remain protected by the surrounding zinc. No rust is formed under the zinc layer in the surrounding areas.

Because alloyed layers of zinc and iron are formed during galvanising which are permanently connected with the steel surface, the adhesive capacity is good.

Hot-dip galvanising is maintenance-free, i.e. no servicing is required. The protection duration until initial servicing can total up to more than 100 years in accordance with the DIN EN ISO 14713. No other corrosion protection system is able to offer such a long period of protection.

The lifetime costs of a conventional corrosion protection system exceed that of the hot-dip galvanisation multiple times over!

The process of hot-dip galvanising is highly efficient with resources and environmentally-friendly in all areas.

Hot-dip galvanising – the production flow:

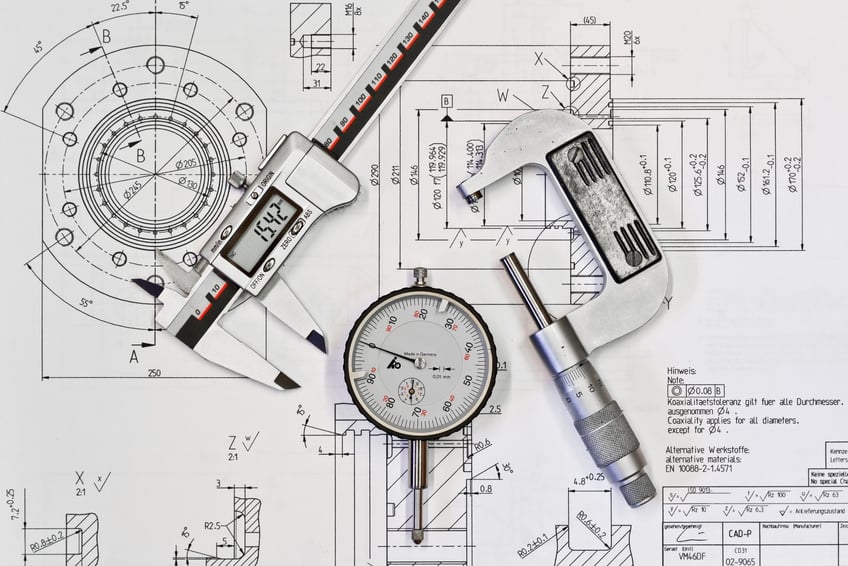

The products run through processes such as preliminary treatment, drying and galvanisation fully automatically and with great precision.

2.At the control station, all processes within the plant can be tracked at all times and are permanently recorded.

3.A completely enclosed preliminary treatment and cleaning of the exhaust air per scrubber helps to achieve exceptionally low emission values which underrun the limit values multiple times over.

5..Lead-free molten zinc acc. DIN EN ISO 1461 and the DASt directive 022 (zinc bath class 1) for galvanisation in line with the standards and a high-quality appearance of the components.