Duplex systems

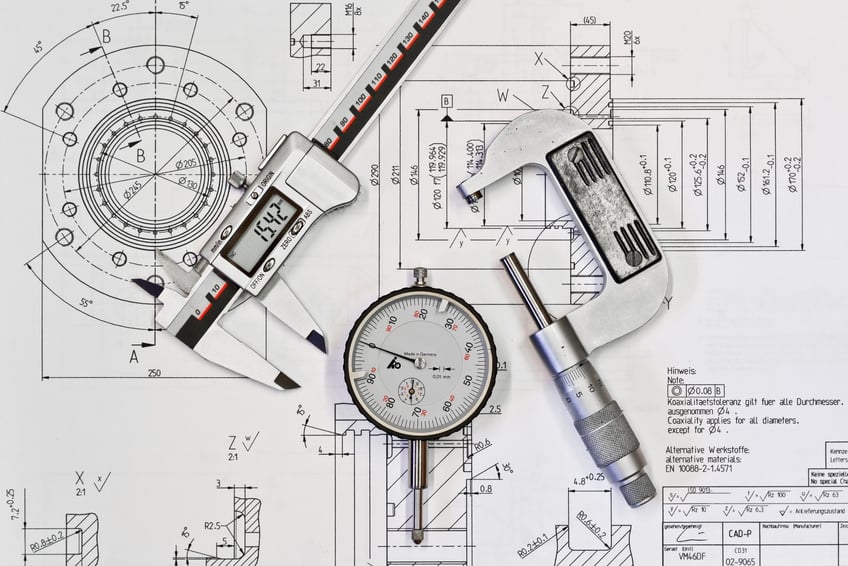

DUPLEX SYSTEMS COMBINE THE CORROSION PROTECTION PROVIDED BY GALVANISATION AND POWDER COATING. THE EXTENSION FACTOR OF THE CORROSION PROTECTION FOR METAL AND STEEL SURFACES LIES BETWEEN 1.2 AND 2.5 DEPENDING ON THE SYSTEM.

Duplex systems: Double the protection for metal surfaces

Double protection is better - this applies in particular for our special duplex procedure for the protection duration of your metal parts or steel surfaces. Here we technologically combine the corrosion protection properties of galvanisation and powder coating. The result: This combination has a substantially longer effect than the respective individual solutions. This is invaluable, amongst other things for elements in facade construction, as these should be optimally protected against the weather.

With us, you will receive both the galvanisation and the coating of your components and steel surfaces from a single source.

Duplex systems – your advantages at a glance:

The robust and maintenance-free part galvanisation preserves the coating against underlying rust penetration. You can choose any colour for the coating process itself and thereby obtain a decorative effect. In addition, the coating protects the zinc against material abrasion through weathering.

Through the double corrosion protection, you can achieve a maximum protection duration for steel surfaces and metal parts.

Duplex system – the production process:

1. A pretreated zinc surface which has been freed of all environmental and process-related contaminations

2. After the automated wet chemical pretreatment process, the parts are taken for powder coating

3. Drying of the components after application of the solvent-free powder coating

4. Finished product Due to the numerous fields of application and the decorative diversity developed over the course of the decades, a wide colour spectrum of powder paints in RAL and special colours is available today.