High-temperature / centrifugal galvanising

CENTRIFUGAL GALVANISING IS RECOMMENDED AS A RELIABLE CORROSION PROTECTION, MAINLY FOR SMALL PARTS SUCH AS SCREWS, NUTS, BULK GOODS OR PRODUCTS WITH SPECIAL REQUIREMENTS ON THEIR SURFACES.

Centrifugal galvanising: Optimum protection for small parts

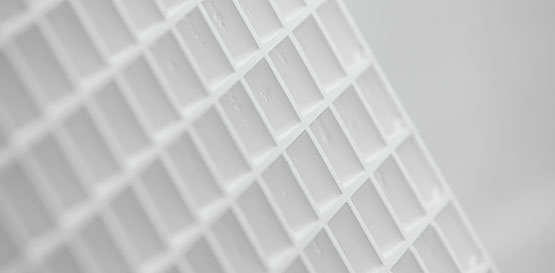

During high-temperature/centrifugal galvanisation, your steel products run through a multi-stage preliminary treatment. In order to achieve even surfaces and perfect fit accuracy, excess zinc is automatically removed during the centrifuging process.

Centrifugal galvanising – your advantages at a glance

Centrifugal galvanising protects small parts perfectly against corrosion - without your products losing the necessary fit accuracy.

In comparison to the classic hot-dip galvanising process, the zinc bath temperature varies from 450°C normal temperature to approx. 530°C high temperature, and is therefore substantially higher. This leads to better drainage characteristics of the zinc from the surface.

Centrifugal galvanising also offers you the same advantages as the classic Hot-dip galvanising.

High-temperature / centrifugal galvanising - the production flow:

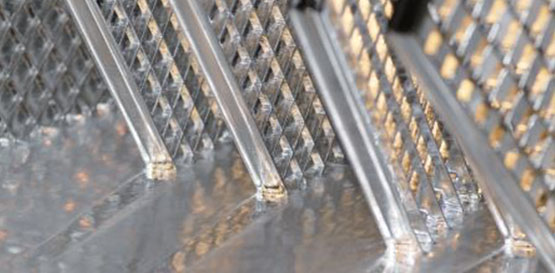

- 1. The small parts are collected in a round basket which has numerous drain openings.

- 2. After the zinc bath, the basket is quickly rotated to centrifuge off the excess zinc.

- 3. After that, the small parts are quenched in a water bath in order to stop them sticking to each other.